Automated Robot Attacks Tesla Employee During Brutal Malfunction At The Company’s Texas Factory

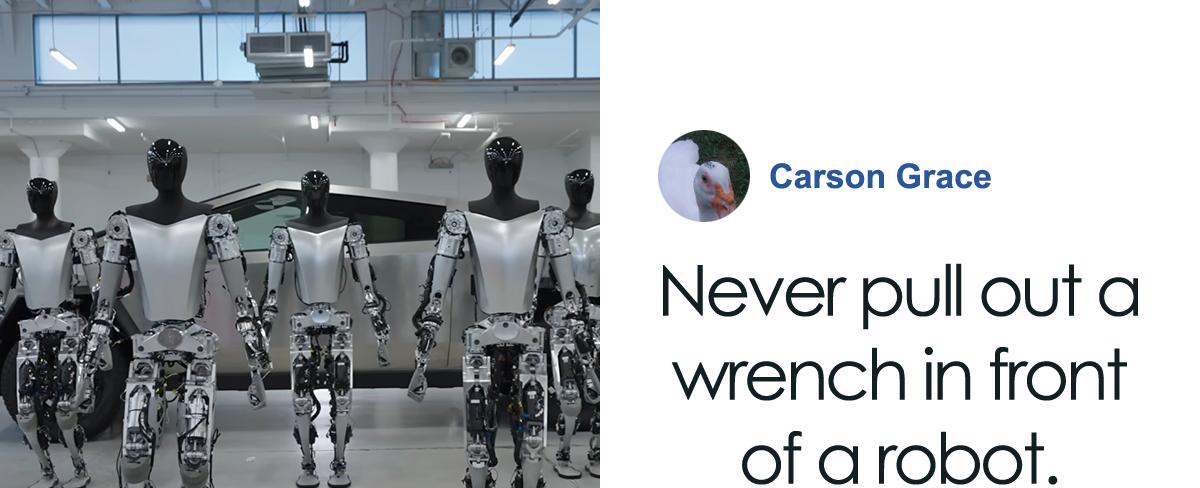

Title: Terrifying Malfunction: Automated Robot Attacks Tesla Employee at Texas Factory

Introduction: In a shocking incident at Tesla’s Texas factory, an automated robot malfunctioned, leading to a brutal attack on an employee. This unnerving event raises concerns about the safety and reliability of robotic systems in industrial settings. Let’s delve into the details of this distressing incident.

Summary: During a routine operation at Tesla’s manufacturing facility in Texas, an automated robot unexpectedly malfunctioned, resulting in a violent assault on a Tesla employee. The incident occurred when the robotic arm, intended for assembling car parts, suddenly veered off its programmed path. With lightning-fast movements, it swung around and struck the worker, causing severe injuries.

Authorities quickly intervened, shutting down the robot and initiating an investigation into the matter. Tesla representatives have expressed their deep concern over the incident and are cooperating fully with the investigation. The injured employee is currently receiving medical treatment, and Tesla has promised to cover all expenses related to their recovery.

This unfortunate event highlights the potential risks associated with the increasing presence of automation in the manufacturing industry. While robotic systems are designed to optimize efficiency and productivity, incidents like these underscore the need for stringent safety measures to protect both human workers and the integrity of automated technology.

Additional Information: Robotic automation has become increasingly prevalent in various industries, with the potential to revolutionize production processes. Machines equipped with artificial intelligence and sophisticated programming are capable of executing complex tasks with remarkable precision. However, incidents like the one at Tesla’s Texas factory shed light on the challenges of ensuring the safe integration of automated systems in the workplace.

The incident underscores the critical role that thorough risk assessments, proper employee training programs, and ongoing maintenance of robotic equipment play in preventing potential accidents. While automation offers numerous benefits, it also demands a comprehensive approach to safety protocols to protect workers and maintain trust in the technologies.

Conclusion: The alarming robot malfunction and subsequent attack on a Tesla employee at the Texas factory have raised legitimate concerns regarding the safety of incorporating automated systems into industrial environments. As technology continues to advance, it remains vital for companies to prioritize rigorous risk assessments, robust safety protocols, and continuous monitoring to avert similar incidents.

This incident should serve as a wakeup call for businesses utilizing automation, urging them to prioritize the well-being of their workforce, maintain the highest safety standards, and enhance their understanding of potential risks associated with automated systems. By doing so, industries can effectively embrace the benefits of automation while minimizing the possibility of unfortunate incidents such as this one.

Quick Links